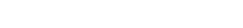

THCR-12

HOME

HOME- Coffee Roaster

- Medium Roaster

- THCR-12

본문

POWER

1Phase 220V 2.5kW/h

HEATING SOURCE

Low Presure gas 37,000kcal/h

WORK CAPACITY

6~14 kg/Batch

WORKING TIME

5~20 mins

-

-

The THCR-12 is a 15kg roaster used in large roaster shops or coffee processing operations. It has a structure in which the cooling tray and roaster body are separate. This allows for the cooling tray to be multi-functional as it can be used for blending as well as cooling. It is an excellent model in terms of production efficiency and product quality.

Semi-Convection Roaster

A rich flavor and aroma is achieved by combining conduction from drum roasting and convection heat. Compared to a direct conduction, semi-convection heat is more uniform and achieves excellent results even for new roasters. The design and airflow allows for excellent, consistent roasts with good development.

Maximizing Thermal Efficiency

The roaster design creates a high thermal efficiency which allows the machine to match any roasting profile. This freedom to control heat and airflow allows for short or long roasts to bring out the best in each type of bean.

Precise Control of Airflow

The damper adjustment function allows you to precisely control the amount of airflow, resulting in delicate flavor and aroma.

Rapid Cooling System

Rapid cooling after roasting is an important factor in preserving flavor and aroma. Proaster cooling design allows for fast cooling times

Fire Safety / Power Failure Safety System

The safety system design shuts off the gas if power is stopped or the exhaust blower stops.

No Overheating Safety System

If the roasting temperature reaches the maximum safety setting temperature then the safety system will turn off the gas.

SPECIFICATION