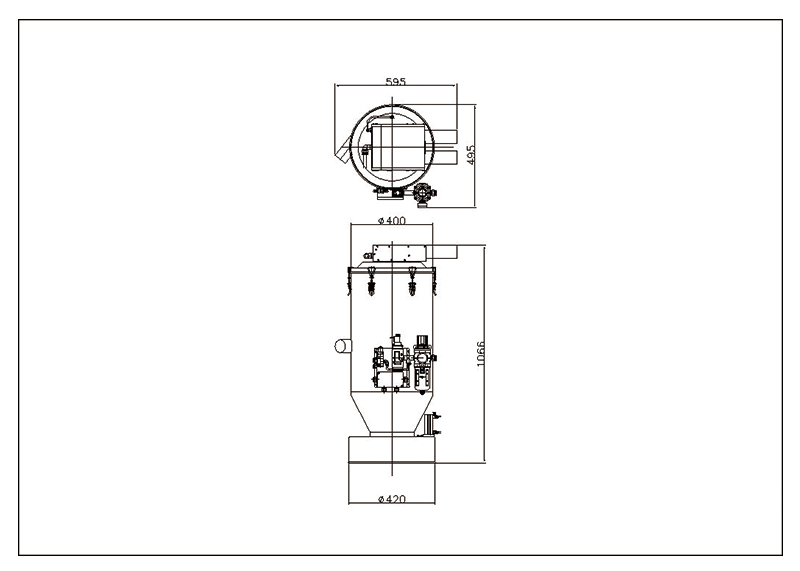

THVE-400

본문

POWER

1Phase 220V 15W/h

WORK CAPACITY

12~16Liter

WORKING TIME

5~25sec

-

-

Vacuum Loader Principle

This vacuum transfer device transfers the raw material of the powder or particle in the suction port to the main body sucked together with the air due to the vacuum generated by the vacuum blower which is connected to the upper portion of the main body and difference of pressure between the suction pipe outlet and inside of the main body. The transferred material is vacuum destroyed, and at the same time, the discharge port at the lower part of the main body is opened and allows free fall of conveyed material.

Vacuum Loader Feature

Leakage of the conveyed powder does not occur due to the use of vacuum pressure. It is connected to the transfer piping, and the arrangement of each production facility is free.

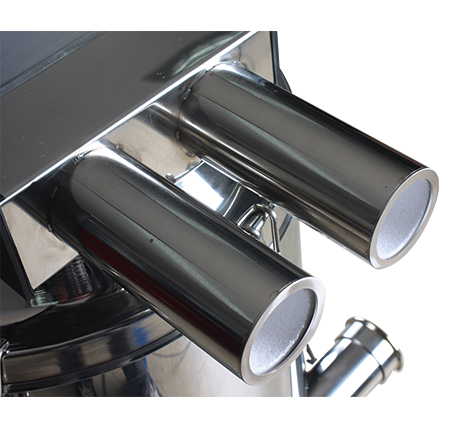

Strong suction power

Achieves high-density and high-weight powder transfer due to high vacuum capacity and strong wind power in proportion to the performance of the vacuum blower.

Filter auto cleaning function

Removes dust on the filter surface to maintain transport efficiency through periodic instantaneous air injection by the built-in compressed air tank

Superior discharge function

Raw materials inside the body are discharged quickly without remaining and no foreign matters occur by friction or abrasion.

Feeding without residual

It is possible to remove the residual of raw material in the feeder or transfer pipe (2-3 idling cycles).

Convenient disassembly and cleaning

It is convenient to disassemble and clean inside of the container or filter without using specific tool.

Raw material damage minimized

Cyclone structure of conveying machine minimizes impact and abrasion when conveying, minimizing destruction of granular material.

Superior performance of the filter

The maximum filter area is applied and the filter material not allowing leakage of the fine powder is used.

Variety of vacuum generator source

Vacuuming by pneumatic ejector pump integrated with main body, and separate motor driven vacuum blower type transfer is available.

Suitability of transfer materials

The following powder or particulate materials may difficult or not possible to transport smoothly

- particles larger than 1/20 times the cross section of the transport pipe

- powder with poor fluidity due to solidification

- non-dried powder containing liquid (oil, water)

- heavy weight powder or particulate materials of apparent specific gravity over 5.

- adhesive or sticky powder or particulate materials

- explosive, flammable powder or particulate materials

Applicable field:

- Application: feeding of the granules or powder in food processing process

- transfer of metal powder, stone powder, inorganic particles, raw material transfer

- injection machine, extruder fillet material transfer

- various kinds of chemical powder material transfer

- feeding of granular materials such as animal feeds and medicines.

SPECIFICATION

HOME

HOME